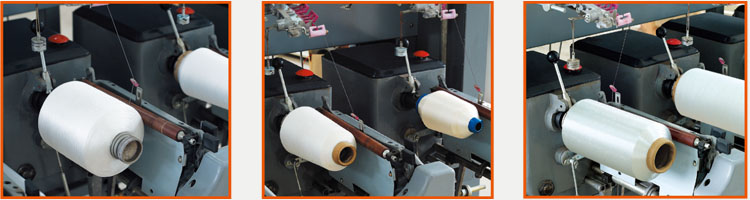

The machine applies multi-functional special-purpose frequency converter matching with mechanical fine cheese winding. It turns from the original mechanical transmission mode to single-spindle, single frequency converter, single motor drive mode so that it is easy in installation and debugging and has less wearing parts. When we use the function of automatic tension control, it can make finished packages keep harmonious elasticity, hardness, and density, and stably enhance the internal quality of the finished packages. It is an ideal equipment for the weaving, knitwear, thread-making, dyeing and filigree manufacture industries etc.

Function features:

We integrate all the electronic components control units etc. into one, so that it results in easy wire connection, reduced exposed parts and convenient assembly and disassembly. One frequency converter spurs on two motors so that main motor and overfeeding motor can independently set the functions. It reaches the technological requirements of inter coordination. The major setting functions are constant thread speed, variable thread speed, increment speed, decrement speed , yarn speed tracking, tension control and so on. We solve the problem of the unstable unwinding tension from the supply packages, to make the winding packages keep harmonious internal and external elasticity, flexibility and density, unless the connection of the unwinding packages or hanks.

The main technical parameters:

Pattern | One sided, Single spindle, single motor, Single frequency converter control |

Model | Upper and lower thread guide |

Spindle distance | |

300mm | |

Wind ratio | 1:2.2、1:3.2,、1:4.2 etc. Other wind ratios can be made for special requirements |

Spindle speed | Spindle speed shall be controlled according to wind ratio, about 1500r.p.m.to 2500r.p.m |

Differential | Independent motor controls dialectical transmission shaft. Every spindle box has dialectical dethickness device |

Bobbin forms | Straight and conical 6",8",9" bobbins. Taper of conical bobbin: 3° 30’(Can customize special specification ) |

Bobbin capacity | Max diameter: 180mm, weight: 250-2000g |

Operation mode | Automatic control can be implemented according to the setting requirements |

Open/shut mode | Slow start, slow brake, quick brake spindle |

Full bobbin automatic stop | It automatically stops at full bobbin according to set data and has self-locking anti-error operation |

Auto-control mode | Opto-electrical switch detection, time-delay period setting, wireless auto-stop and auto-shut of the function |

Spindle category | It has bobbin rewinding and shelf thread in skeins rewinding according to the requirements. You can additionally install oiling device, |

Motor | 380V/220V 120W/錠,0.72KW/節(jié), 2.88KW/臺 |

Machine dimension | 6spindles/section, 2.00x0.90x1.11M, 24spindles/machine, 7.70x0.90x1.11M |

Machine Weight | 6spindles/section, Weight:420kg, 24spindles/machine, Weight:1680kg |

Related products

Add:No. 27, Xingfeng Road, Xiaomen Industrial Zone, Baifeng Town, Beilun District, Ningbo, Zhejiang, China Tel:+86-574-86725666 013819874997 Fax:+86-574-86727197 E-mail:[email protected]

Copyright ? Ningbo Yongfu Textile Machinery Co., Ltd.